Hot New Products - Batch Inclusion Valve Bags for Silica – Zonpak

Hot New Products - Batch Inclusion Valve Bags for Silica – Zonpak Detail:

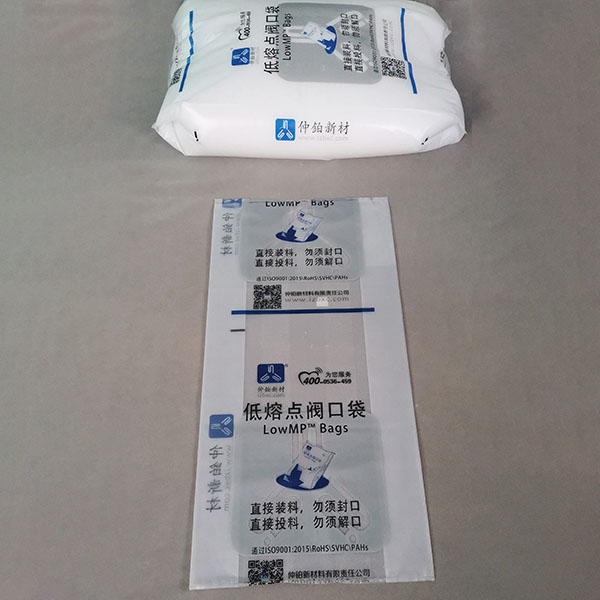

Silica for rubber industry (also called white carbon black) is usually packed with kraft paper bags. The paper bags are easy to break during transportation and difficult to dispose after used. To solve these problems, we have specially developed low melt valve bags for silica manufacturers. These bags can be direct put into an internal mixer because the packaging bags can easily melt and fully disperse in the rubber compounds as a minor effective ingredient. Different melting points (65-110 deg. C) are available for different using conditions.

BENEFITS:

- No fly loss of materials

- High speed packaging

- Easy piling up and handling of materials

- Accurate adding of materials

- Cleaner mixing area

- No need for disposal of packaging waste

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1200 mm

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Hot New Products - Batch Inclusion Valve Bags for Silica – Zonpak, The product will supply to all over the world, such as: USA , Portugal , America , We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our merchandise are favored by domestic and foreign customers. With your support, we'll build a better tomorrow!

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!