Manufacturer for Low Melt FFS Film Roll Stock - EVA Packaging Film for Rubber Curing Agent – Zonpak

Manufacturer for Low Melt FFS Film Roll Stock - EVA Packaging Film for Rubber Curing Agent – Zonpak Detail:

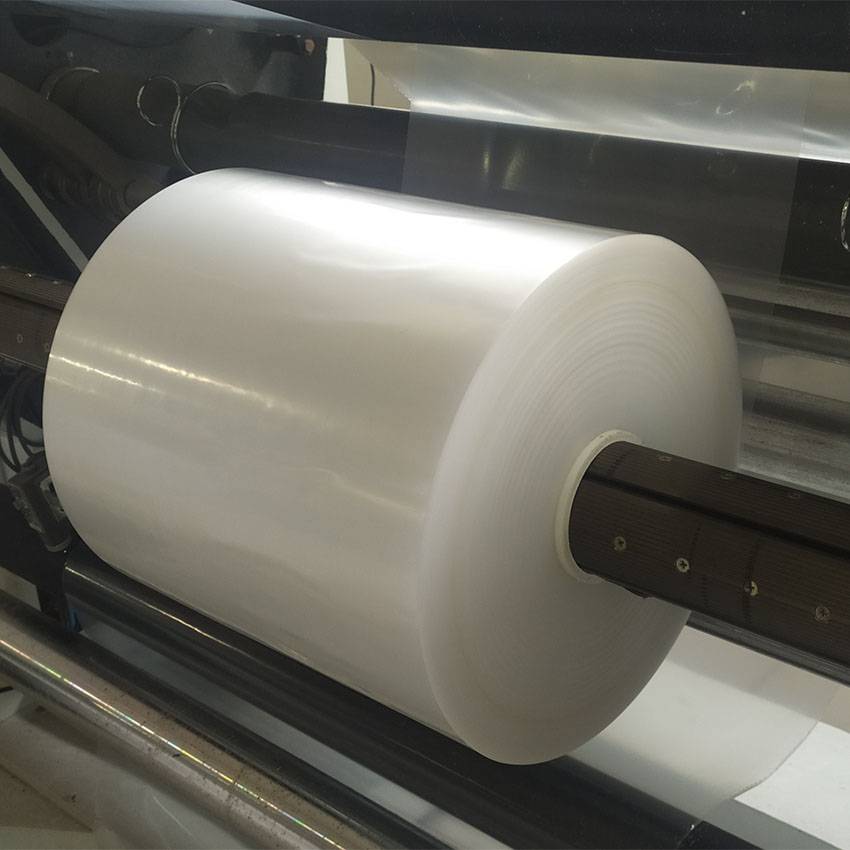

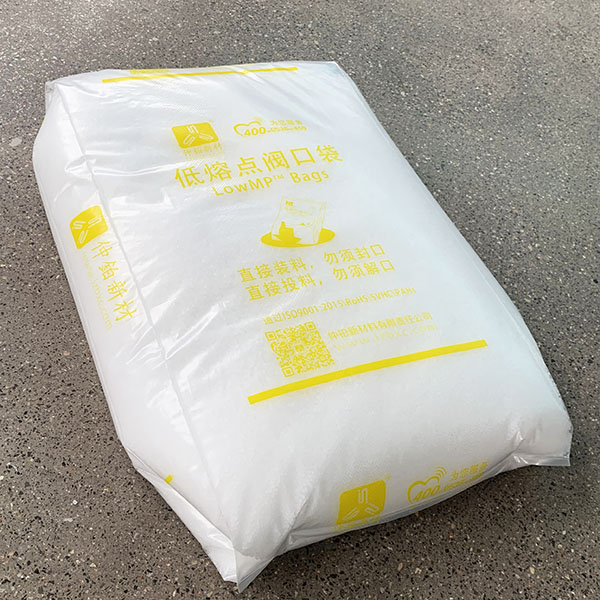

ZonpakTM EVA packaging film is a special kind of plastic film with specific low melting point mainly used for packaging of rubber chemicals. Curing agent is an important chemical used in rubber compounding and mixing, but only a little amount is needed for each batch. Rubber chemical suppliers can use this film with automatic form-fill-seal machine to make little bags of curing agent for the users’ convenience. Due to the film’s specific low melting point and good compatibility with rubber, these little bags can be direct put into an internal mixer in the rubber mixing process, the bags will melt and fully disperse into the compounds as a minor effective ingredient.

SPECIFICATION:

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 30-200 micron

- Film width: 150-1200 mm

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Manufacturer for Low Melt FFS Film Roll Stock - EVA Packaging Film for Rubber Curing Agent – Zonpak, The product will supply to all over the world, such as: Latvia , Peru , Congo , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.