Manufacturing Companies for Hot Sealed EVA Bag - Low Melt Bags for Tire Industry – Zonpak

Manufacturing Companies for Hot Sealed EVA Bag - Low Melt Bags for Tire Industry – Zonpak Detail:

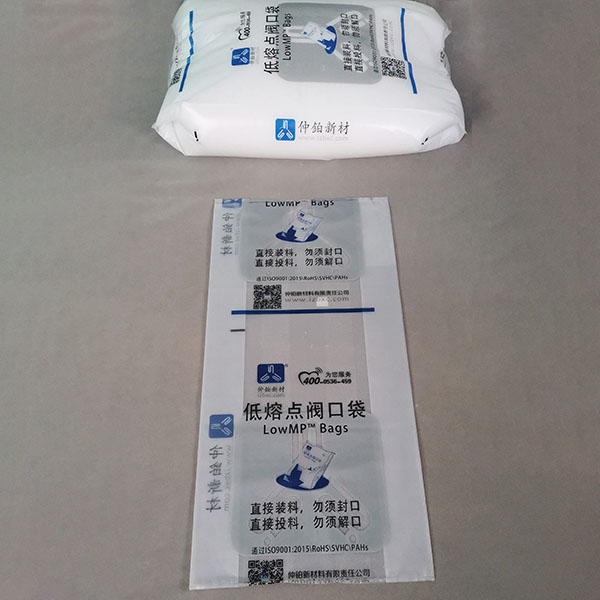

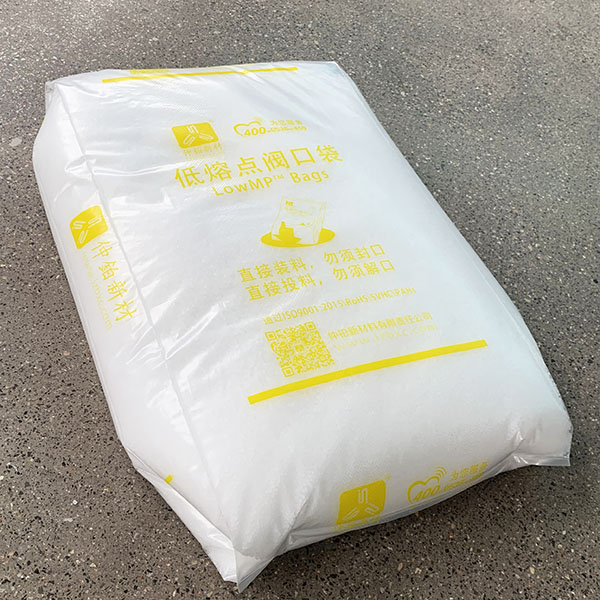

ZonpakTM low melt bags are also called rubber compounding bags or rubber ingredient bags in the tire industry. The bags are specially designed for packing rubber additives and chemicals used in the compounding or mixing process.

Bags with different melting points are suitable for different mixing conditions. Bags with melting point 85 deg. C are the most often used, while bags with melting point 72 deg. C are used for adding of accelerators. Improving work environment, ensuring accurate adding of additives and raising production efficiency are the main benefits of using low melt bags.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

We constantly continually give you essentially the most conscientious client provider, plus the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Manufacturing Companies for Hot Sealed EVA Bag - Low Melt Bags for Tire Industry – Zonpak, The product will supply to all over the world, such as: Amsterdam , Iran , Jordan , "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.