New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak

New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak Detail:

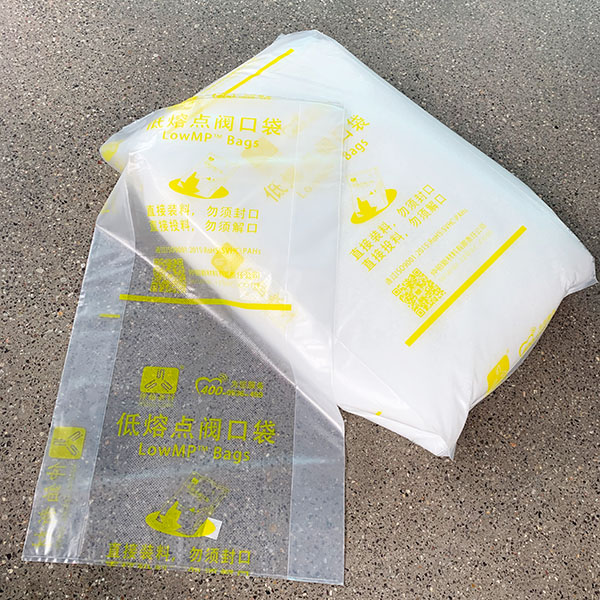

Low melt valve bags are designed for the industrial packaging of rubber and plastic additives. Using the low melt valve bags with an automatic filling machine, material suppliers can make standard packages e.g. 5kg, 10kg and 25kg which can be direct put into a mixer by the material users. The bags will melt and fully disperse in the rubber or plastic mixture as a minor effective ingredient in the compounding and mixing process.

BENEFITS:

- No fly loss of materials

- Improved packing efficiency

- Easy stacking and palletizing

- Assure accurate adding of materials

- Cleaner work environment

- No packaging waste left

APPLICATIONS:

- rubber and plastic pellet or powder, carbon black, silica, zinc oxide, alumina, calcium carbonate, kaolinite clay, rubber process oil

OPTIONS:

- Gusset or block bottom, embossing, venting, color, printing

SPECIFICATION:

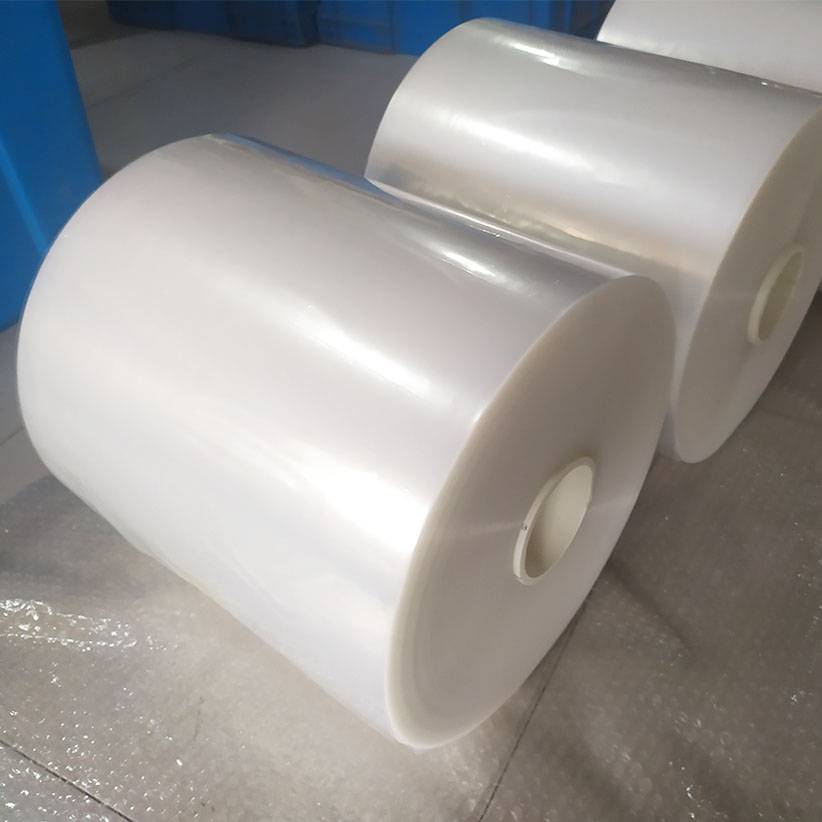

- Material: EVA

- Melting point: 65-110 deg. C

- Film thickness: 100-200 micron

- Bag width: 350-1000 mm

- Bag length: 400-1500 mm

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for New Fashion Design for Degassing Valve Bag - Low Melt Valve Bags – Zonpak, The product will supply to all over the world, such as: Guyana , luzern , Algeria , Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!