OEM Supply VFFS Packaging Film - EVA Batch Inclusion Film – Zonpak

OEM Supply VFFS Packaging Film - EVA Batch Inclusion Film – Zonpak Detail:

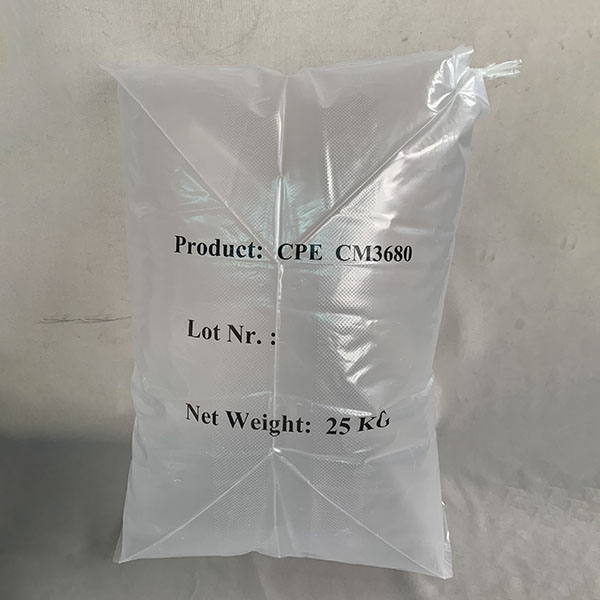

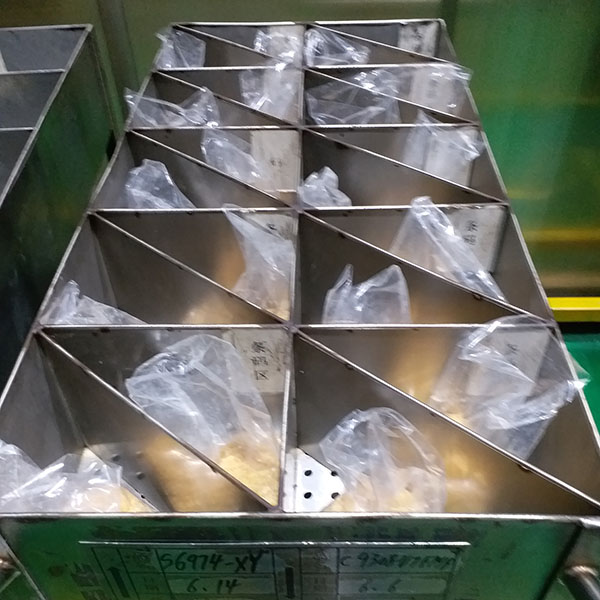

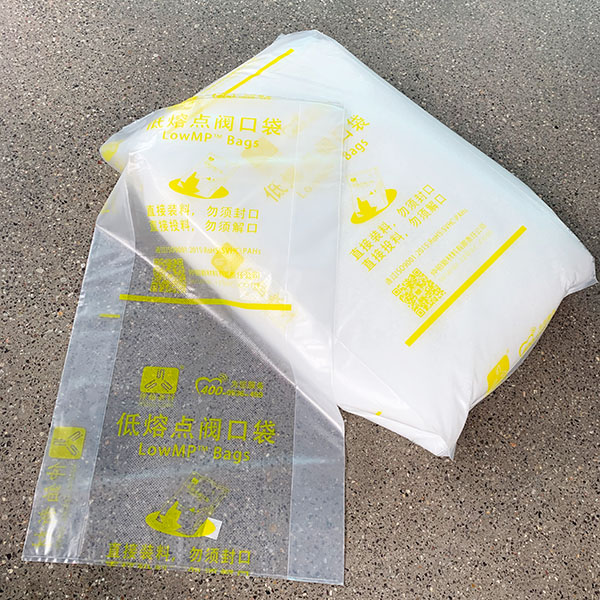

ZonpakTM EVA batch inclusion film is a special kind of packaging film with specific low melting point. It is mainly used on the automatic FFS (form-fill-seal) packaging machine to make little packages (100g-5000g) of rubber additives or chemicals. Due to the film’s property of low melting point and good compatibility with rubber and plastic, these little packages can be direct put into an internal mixer during mixing process at the user’s end, and the bags made of the film will melt and fully disperse into the mix as an effective ingredient. It brings convenience to the material users and eliminates packaging waste disposal.

Different melting points are available according to customers’ requirement. Stable chemical properties and high physical strength of the film make it suitable for most rubber chemicals and automatic packaging machines.

|

Technical Standards |

|

| Melting point | 65-110 deg. C |

| Physical properties | |

| Tensile strength | MD ≥16MPa TD ≥16MPa |

| Elongation at break | MD ≥400% TD ≥400% |

| Modulus at 100% elongation | MD ≥6MPa TD ≥3MPa |

| Appearance | |

| Surface of the product is flat and smooth, there is no wrinkle, no bubble. | |

Product detail pictures:

Related Product Guide:

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for OEM Supply VFFS Packaging Film - EVA Batch Inclusion Film – Zonpak, The product will supply to all over the world, such as: Adelaide , Mali , Netherlands , Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.